Any type of road work will require uniform spraying of bitumen prior to laying of hot mix asphalt. This is where the super-efficient Atlas bitumen sprayer comes into picture. Its job is to uniformly spray bitumen on the road while moving – so that hot mix asphalt can be laid for road building. Truck mounted bitumen distributors are highly accurate and efficient. They are preferred by road contractors because of the accuracy they have to offer.

Its specialty is that it has to handle a very sensitive material – bitumen. The handling of bitumen and its spraying has to be done at a very specific temperature so that desired spraying result can be achieved. Since Atlas make bitumen emulsion sprayers are truck mounted they can be easily taken to places. The demand for high quality equipment is on a rise because it has the ability to get the work done with fewer efforts.

Atlas manufactures and exports bitumen pressure distributors in below tank capacities:

• 4 tons

• 6 tons

• 8 tons

• 10 tons

• 12 tons

All the bitumen sprayer manufactured are with direct heating system. The usable capacity will be slightly less as some amount of bitumen will be lying above heating coils.

Qualities of Efficient Bitumen Sprayer:

There are certain qualities that will make an efficient bitumen sprayer. The best and preferred quality for an efficient pressure distributor for bitumen will be its efficient spraying. Once the truck mounted tar sprayer is moving it should be able to uniformly spray bitumen on the surface.

Below are the qualities that will make Atlas bitumen sprayer stand out from the competition:

• Chassis design: The chassis design should be in such a way that machine can be fitted to any suitable truck chassis. Along with that the machine should be used with any new or old truck chassis.

• Engine: It is a very important component. We use Kirloskar make diesel engine of 25 HP capacity which is very efficient, smooth and proven.

• Spray bar length: It is very much possible to customize the spray bar with Atlas tar sprayers. The spray bar as foldable type so that it is easy to move in small places. There are some key advantages of the sprayer bar like

o Standard offered width of spray bar is 2.4 meters.

o Extended spraying width is 4.5 meters when fully open

o Spray bar with 6 meters spraying width can also be provided.

o Nozzles are adequately spaced out.

o Spray bar open-close is operated pneumatically.

o Pressurized cleaning system using air and diesel to clean all pipelines.

• Storage tank: A thermally insulated tank from all the sides will ensure that bitumen stays hot for a long time.

• Cleaning system: Since bitumen is very sticky material it is very important to have a cleaning system. All Atlas make bitumen sprayers are equipped with a pressurized cleaning system for cleaning the pipelines at the end of operation.

• What about the sides of the roads: There is a hand spray bar provided with the machine for spraying bitumen on the sides of the road.

• Factory testing: The equipment is factory tested prior to dispatch so that you receive a worry-free product. Once the sprayer arrives at the site it is very easy to install the same on your truck.

Bitumen Pressure Distributor Components:

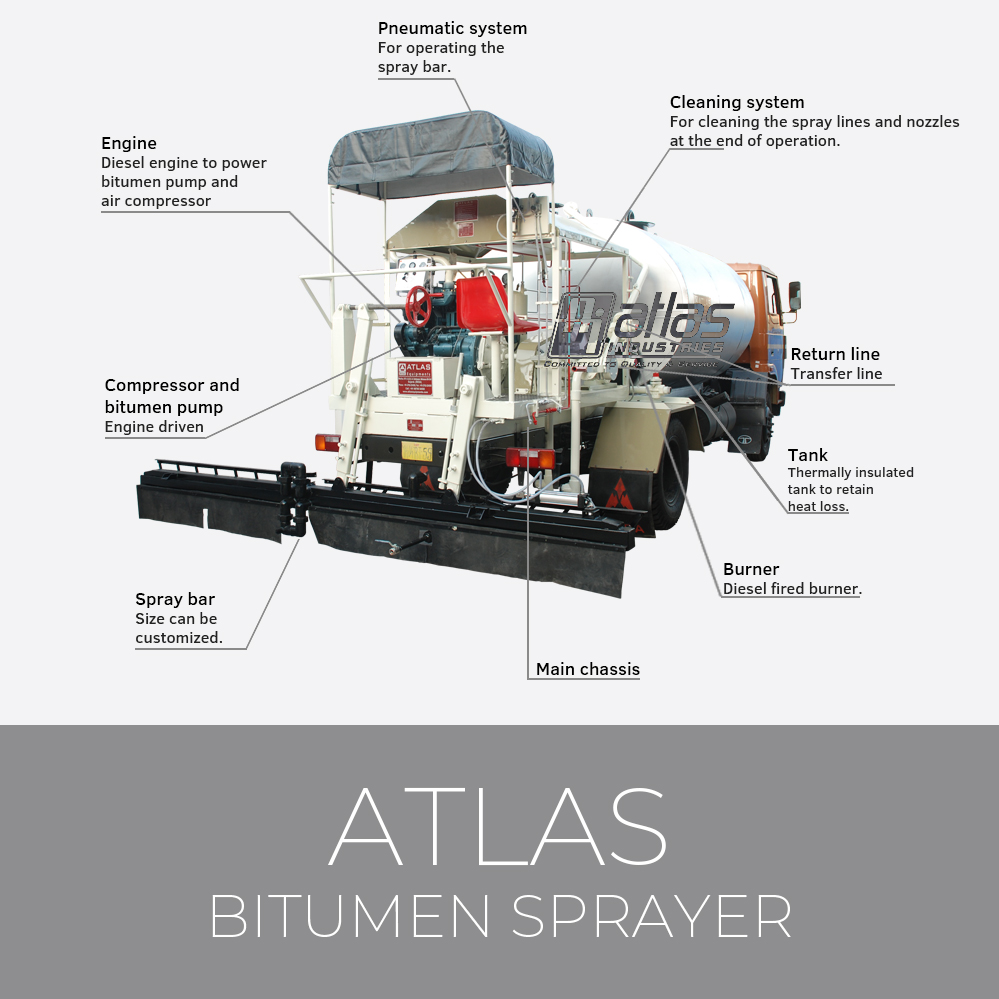

The main components of bitumen pressure distributor are storage tank for bitumen, engine, air compressor, bitumen pump, burner, spray nozzles fitted on spray bar, hand burner. It is possible to customize the sprayer chassis so that it can fit your new or old suitable truck chassis. We can help you select a suitable truck chassis prior to your purchase. Below are the details of the components of Atlas bitumen pressure distributor.

• Storage tank: Any capacity machine can be provided. The tank is fully insulated from all sides. It is fitted with a strong and efficient burner that works with diesel.

• Engine: It drives the bitumen pump as well as the air compressor. It’s a strong and powerful engine suitable for efficient and smooth operation.

• Bitumen pump and air compressor: The bitumen pump is heavy duty for smooth operation. Air compressor is double cylinder equipped for smooth operation.

• Spraying system is efficient and proven mechanism for free flow of bitumen.

• Cleaning system will use air and diesel to clean the pipelines of bitumen sprayer.

• Return line design: Return line is designed to allow free flow of bitumen.

We have manufactured and exported many bitumen pressure distributors. The quality of the equipment here is very important. We make sure that the equipment offered will be best suitable to work with your existing or new truck. The integration or installation on the truck has to be very smooth and tension free process for our customers. Get more information Contact Atlas Industries.